Design for the Future

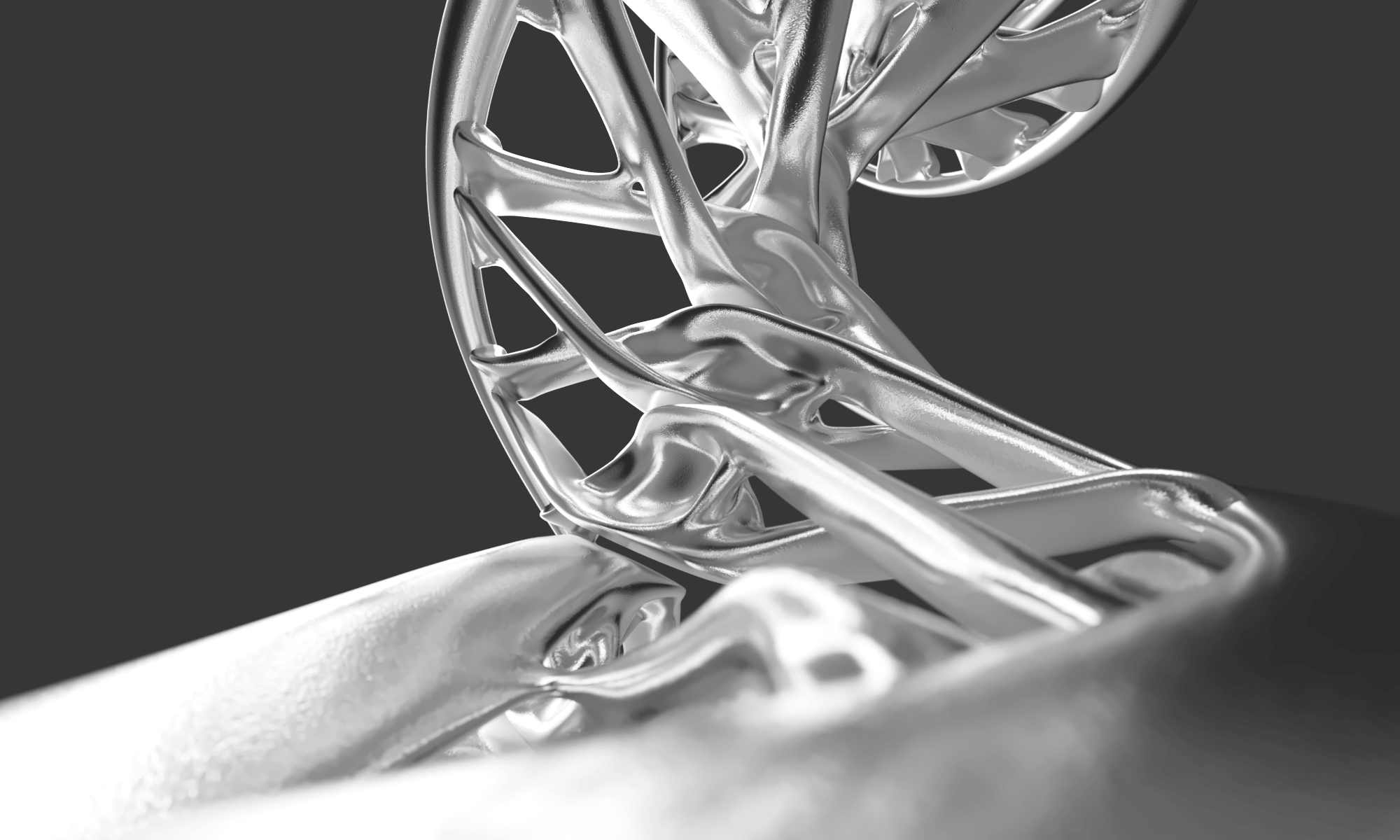

Realize the value of generative design for manufacturing.

Addiform’s generative design services afford your team the ability to explore optimized part geometries specifically tailored to your application’s needs. Whether by coordinating with your own in-house engineering team, or utilizing our network of engineering experts, Addiform can create an accurate digital model of your application from which to generate part geometry.

How it works:

A generative designer inputs a minimal set of engineering criteria into an algorithm trained by machine-learning in order to automatically synthesize geometry. The end result is a highly-optimized, often organic in appearance, manufacture-ready CAD model that is geometrically optimized for the given load cases.

Some of the inputs used to synthesize geometry:

- Areas to preserve

Bosses, mounting locations, etc. - Regions to avoid

Other components, user-access requirements, etc. - Material type and properties

Yield/Tensile Strength, Young’s Modulus, Poisson’s Ratio, etc. - Manufacturing method

2, 3, or 5 axis CNC milling, additive manufacturing, etc.

Save money and increase efficiency with highly-optimized, lightweight parts synthesized by generative design.

Addiform offers a quick, easy, introductory “one-and-done” generative design service for clients who already have a deep understanding of the engineering of their problem.

We also offer in-depth, full-service packages that can more deeply analyze the application from the beginning, uncovering the root of the engineering problem at hand, as well as discovering multiple novel solutions.

Contact us now to learn more about generative design.

The Future, Today

Harness the freedom of hybrid-additive manufacturing.

Additive manufacturing is nothing new. Hybrid-additive manufacturing is the future. It combines the best of both manufacturing worlds: traditional and additive. Freedom of design is maximized when the use of digital, direct-from-CAD manufacturing techniques are combined with the material properties and reliability of traditional methods.

Through the use of technologies like silicone mold-making and investment casting, we can produce your parts with the geometry and material that you require.

Contact us now to begin making the parts of the future, today.

About Us

Addiform specializes in additive manufacturing and generative design.

Since 2015, we have helped clients achieve their goals through additive manufacturing as X3D Technologies Inc.

In 2020, we began offering generative design services for manufacturing under our new brand: Addiform.

Founders Nathan & Nerea Buxton